Millwide Automation

Overview

Basic and most common automation stations in Palm Oil Mill are as follows:

9

Fruit Reception Station

|

|

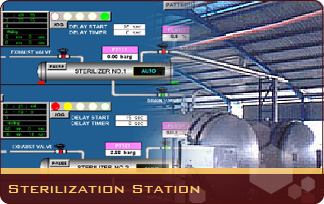

Sterilization Station

|

|

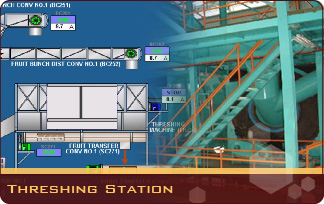

Threshing Station

|

|

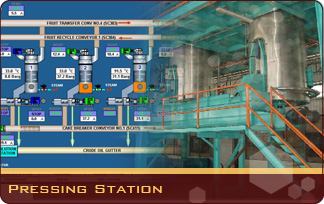

Pressing Station

|

|

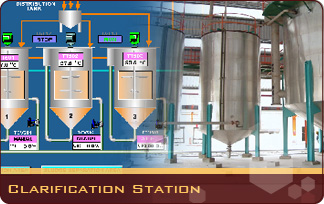

Clarification Station

|

|

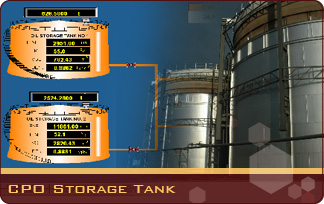

CPO Storage Tank

|

|

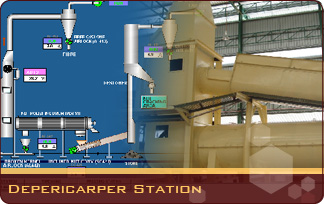

Depericarper Station

|

|

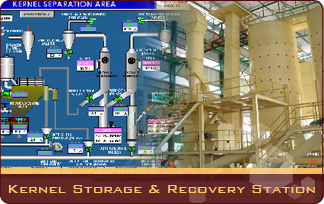

Kernel Storage and Recovery Station

|

|

Nut Cracking Area

|

|